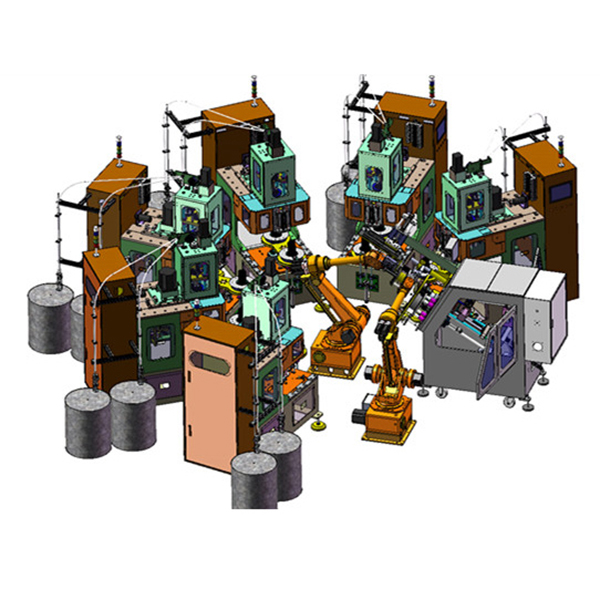

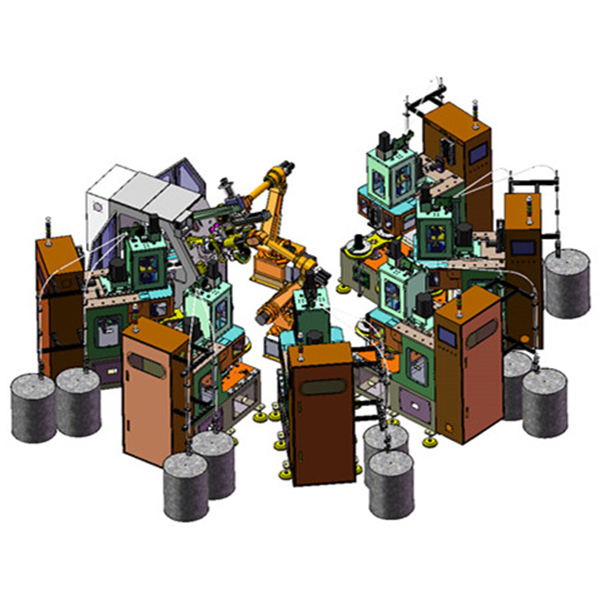

Motor stator umgca wemveliso oluzenzekelayo (imo yerobhothi 2)

Ingcaciso yeMveliso

● Irobhothi isetyenziselwa ukudlulisa iikhoyili zomatshini wokujika omileyo kunye nomatshini oqhelekileyo wokufaka ucingo lwe-servo.

● Ukugcina ukusebenza kweengcingo zokujija nokufaka.

Ulwakhiwo

Izisombululo kwiingxaki eziqhelekileyo emva kokuhlanganiswa komgca we-rotor ngokuzenzekelayo

I-rotor ye-automatic assembly sisixhobo esizenzekelayo esakhiwe ngama-activators, i-sensor elements, kunye nabalawuli.Iimpazamo kwi-rotor automated assembly line inokubangela ukungahambi kakuhle okanye ukungasebenzi ngokupheleleyo.Kule nqaku, sixubusha iindlela ezine eziqhelekileyo zokuchonga iimpazamo kwimigca yokuhlanganisa i-rotor ngokuzenzekelayo.

1. Ukuqhuba uhlolo olubanzi lonikezelo lwamandla, umthombo womoya, kunye nesixhobo somthombo we-hydraulic kwi-rotor automatic line assembly.Uninzi lweengxaki zomgca we-rotor ngokuzenzekelayo zivela kwiingxaki zokunikezelwa kwamandla, umthombo womoya kunye nomthombo we-hydraulic.Xa ujonga, qiniseka ukuba umbane wendawo yokusebenzela wanele kwaye zonke izixhobo zisebenza ngokuqhelekileyo.Jonga umthombo woxinzelelo lomoya kunye nempompo yehydraulic efunekayo kwi-asembly line hydraulics.

2. Khangela ukuba ngaba indawo yenzwa kwi-rotor i-automatic line assembly itshintshile.Ngokuhamba kwexesha, abenzi boluvo banokufumana imiba yobuntununtunu, ukungasebenzi kakuhle, okanye utshintsho kwindawo.Isikhundla sokufumanisa kunye nokuvakalelwa kwenzwa kufuneka kuhlolwe rhoqo, kulungiswe ngokufanelekileyo xa isikhundla sitshintsha, kwaye sitshintshwe ngokukhawuleza xa sihluleka.Iingxaki ze-Vibration ngexesha le-rotor ehambayo yomgca wokuhlanganisana kunokubangela ukuba i-sensors ekhululekile.Kubalulekile ukuqinisekisa ukuba i-sensor ikwindawo eqinileyo.

3. Jonga i-relay, ivalve yokulawula ukuhamba kunye nevalve yokulawula uxinzelelo.Umsebenzi we-relay ufana ne-sensor ye-magnetic induction sensor, kwaye iingxaki zexesha elide lokumisa ziya kuchaphazela ukusetyenziswa okuqhelekileyo kwesekethe kwaye kufuneka zitshintshwe.Inkqubo ye-pneumatic okanye i-hydraulic yomgca wendibano, ukuvulwa kwe-valve ye-throttle, i-spring yokulungiswa koxinzelelo lwe-valve yoxinzelelo, njl.njl iya kulahlekelwa ukuqina okanye i-slip ngenxa yeengxaki ze-vibration, kwaye ifuna ukugcinwa rhoqo ngexesha lokusetyenziswa ngokuqhelekileyo.

4. Qwalasela uqhagamshelwano lwesekethe yombane, ipneumatic kunye nehydraulic.Ukuba ukukhangela indawo yempazamo ayibonakalisi umthombo wengxaki, jonga isimo sesiphaluka sesixhobo sesekethe evulekileyo.Qinisekisa ukuba iiconductors ze-wireway azikho contoured ngenxa yemicimbi yokukhupha kwaye uhlolisise i-bronchus nayiphi na umonakalo okanye imibimbi.Jonga ukuba i-oyile ye-hydraulic ivalekile.Ukuba i-trachea ishwabene kakhulu, kufuneka itshintshwe ngokukhawuleza.Ukuba kukho ingxaki kumbhobho weoli we-hydraulic, kuya kufuneka kwakhona ukutshintshwa.

5. Ukuba le miqathango ingentla ayikho, amathuba okuba iingxaki zeprogram kwisilawuli somgca we-rotor ngokuzenzekelayo uphantsi.