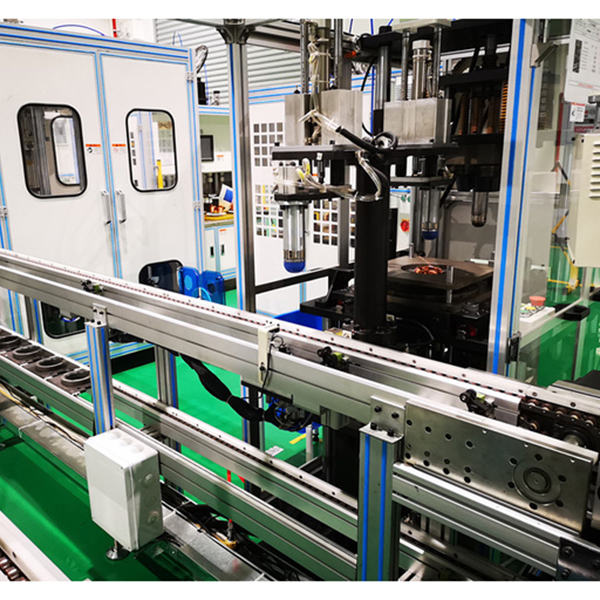

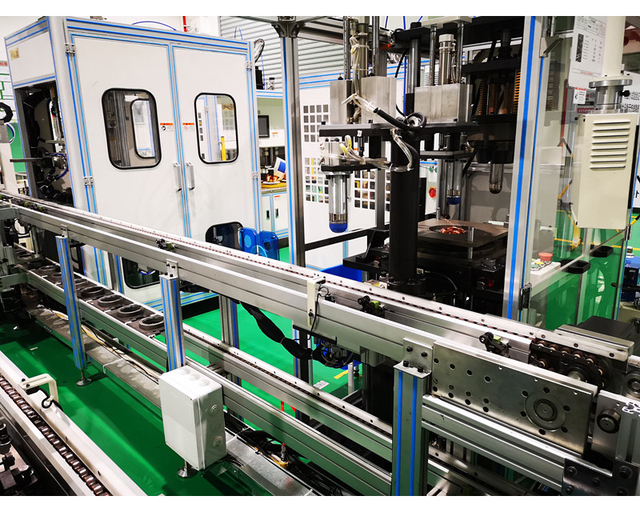

Umgca wemveliso ozenzekelayo weStator (imowudi ye-speed chain 2)

Ingcaciso yeMveliso

Umgca wokuvelisa ngokuzenzekelayo udlulisela i-tooling ngokusebenzisa umgca wokuhlanganisa i-double-speed chain, (kubandakanywa ukufakwa kwephepha, ukuvuthwa, ukudibanisa, ukubunjwa okuphakathi, ukubopha, ukugqiba kunye nezinye iinkqubo) kunye nokumisa okuchanekileyo kunye nokusebenza okuzinzile nokuthembekileyo.

Ulwakhiwo

Indlela yokulungelelanisa ngoku kwi-rotor umgca we-automatic spot welding machine?

I-rotor automatic line spot welder yayiqale yaxhotyiswa ngesilawuli se-AC kunye ne-AC spot welder, kodwa umbane ongazinzanga we-AC spot welder kunye nengxaki ye-welding ebonakalayo ibangele ukuba ithathelwe indawo yi-intermediate frequency inverter DC controller, i-intermediate frequency inverter, kunye ne-spot welder. Kweli nqaku, siza kuxubusha iindlela ezahlukeneyo zohlengahlengiso lwangoku lwe-rotor ye-wire spot welder:

1. Ulawulo lwemowudi yamandla rhoqo: Ukusebenzisa imowudi yamandla rhoqo Q=UI inokuphepha ukunyuka kwe-electrode resistivity kunye nobushushu xa usebenzisa imo eqhubekayo yangoku, kunye nokuthintela i-thermal Q=I2Rt ekuphakameni. Ngokusebenzisa imowudi ethile yamandla Q=UI, ubushushu bungalingana.

2. Umlinganiselo we-voltage yomgca we-rotor othomathikhi ezimbini: umlinganiselo wombane kufuneka uqhutywe ngokusondeleyo kwiipali ezilungileyo kunye nezibi. Ingongoma kukulawula ixabiso le-voltage phakathi kweepali ezilungileyo kunye nezibi, kungekhona i-voltage yesiphaluka sonke.

3. Ukutshintsha ukusuka kwi-1-pulse discharge ukuya kwi-2-pulse discharge okanye i-3-pulse discharge (ixesha lokukhutshwa lilonke lihlala lingatshintshi), kunye nokunciphisa ixabiso lamandla (okanye ixabiso langoku) lincinci. Ukuba i-pulsed discharge isetyenzisiwe, ixabiso lamandla liya kufuneka linyuswe ukufezekisa ubushushu obufunwayo be-welding. Ukuba i-double-pulse discharge isetyenzisiweyo (ixabiso lokuqala lokukhupha i-pulse libekwe phantsi, kwaye ixabiso lesibini lokukhupha i-pulse libekwe phezulu), ixabiso lamandla (okanye ixabiso langoku) lingancitshiswa kakhulu kwi-welding. Ukuncitshiswa kwexabiso lamandla (okanye ixabiso langoku) kubangela ukunciphisa ukugqoka i-electrode kunye nokuphucula ukuzinza kwe-welding. Q=I2Rt ithetha ukuba ukuqokelelwa kobushushu kuchaphazeleka ngakumbi ngokunyuka kwexabiso langoku. Ngoko ke, xa ubeka iiparamitha, nciphisa ixabiso langoku (okanye ixabiso lamandla) libe lincinci.

4. Buyisela i-electrode ye-tungsten kwi-hook phantsi kwe-welder yendawo kunye ne-electrode engalunganga, kuba i-current iphuma kwi-hook ukuya kwi-electrode ye-tungsten, ibangela "intshukumo ye-electron", okubangela ukuba ii-athomu zetsimbi ezincinci zigeleze kwi-electrode, iyenze ibe mdaka kwaye iphelile. "Intshukumo yombane" ithetha ukuba ukuhamba kwee-electron zentsimbi zevalence kubangela intshukumo yomzimba wolwelo oqulethe iiathom zesinyithi.

Ngokwale ndlela ingentla, uhlengahlengiso lwangoku lwe-rotor oluzenzekelayo umatshini we-welding we-wire spot ungagqitywa ngempumelelo. Eli nqaku lijolise ekuqondeni ngcono ukusetyenziswa kwe-electromechanical ye-rotor automatic wire spot welders ukuphucula ukusebenza kakuhle kwemveliso kunye nokugcina amandla. Ukongezelela, ukugcinwa rhoqo rhoqo kufuneka kuhlanganiswe ekusebenzeni kwemigca yokuvelisa i-rotor ngokuzenzekelayo. Oku kunegalelo kubomi bayo obude kunye nokuchaneka kokusebenza.